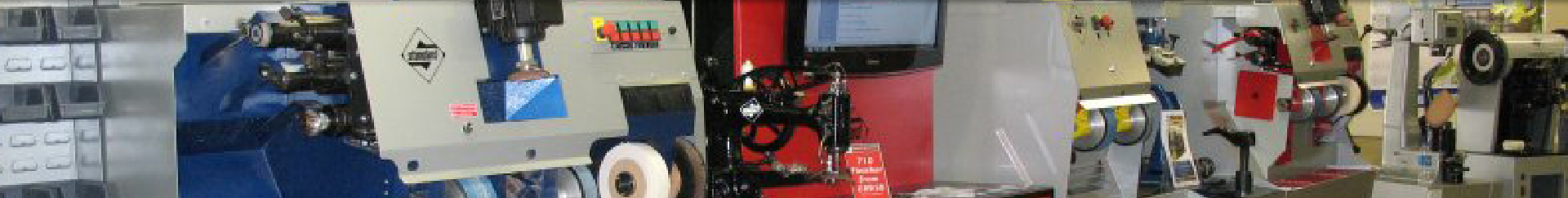

At Standard Engineering we make the 700 range of finishers – you can hardly fail to have noticed from our adverts and editorial over the years! However, in the 120 years of the company’s existence, this build period represents a small part of our history.

In fact Standard only began to build the 700-range of finishers following the takeover of Whitfield Wylie at the start of the present Century. Standard acquired the Whitfield production facility in Kettering and it made sense to carry on building the Whitfield range of equipment rather than getting everyone to start over with the then Standard range of Lynx Finishers, Tiger Presses, and, no doubt, Ocelot Heat Lamps!

The major upshot of this decision was to begin the gradual obsolescence of the Lynx Tiger combination. Once a company is no longer geared up to manufacture a particular model, the number of parts stocked for those machines reduces over time. Within a year or two of the takeover, the new Standard Engineering could not have offered new Lynx / Tiger machinery if it wanted to. Although we have continued to carry some of the more obvious consumable items for the Lynx/Tiger range, we have now reached the stage where we would be loathe to offer to recondition this range either.

Too many parts are no longer made or stocked for us to confidently offer a fully reconditioned version, backed with our guarantee. Lynx/Tiger have joined the dozens of makes/model combinations of shoe repair machinery that are no longer built, reconditioned or particularly supported.

Who can remember the Standard “Dove” finisher? The “Little Gem?” The “Digbeth?” Or the Whitfield “100”, “200”, “500”? Or “Europa?” Or the “C92 – less-than-affectionally known as the “Fish and Chip” machine? All gone. All obsolete. Entire ranges of equipment that are no longer supportable.

They turn up on E-bay every now and again, and if punters buy them, get them going, and squeeze a few additional years out of the kit, then fair play to them. We usually know an ancient beast of a finisher has been put on Ebay as we will get a call asking the cost of motors, buttons or bayonet fittings for a “Standard 2A Combination Finisher”, or a Whitfield “Model H.”

It’s not just our old kit which has been consigned to the history of shoe repairing. Numerous other companies have built shoe repair equipment over the years and are either no longer with us, or operating at a much reduced capacity, supplying refurbished units and spares only.

All of which brings us back to the 700 range of finishers. The original ones are well over 30 years old, but because the basic design has not been changed too much the vast majority of the components we use on our current builds can be used on older models.

This means a couple of things. Firstly, if you have an old Model 700 in need of parts or consumables you are in a very fortunate position, because, chance are, we’ll have them and be able to supply from stock at a reasonable cost.

It also means that the 700 Finisher retains a much greater sales or trade-in value with us because it is a tradeable commodity. We can fully recondition them and offer back to the market, content that they will be supportable for the foreseeable future, and this is reflected in the prices we offer. That’s not something you can say for the vast majority of makes and models out there, whether they are old stuff we made, equipment from the Continent, or the bargain-basement kit from even further East.